The Arahant Project

- India -

Arahant in Buddhism means fully enlightened person, who might teach others, but not as the one who rediscovered the teachings, just as one who learned it from a current dispensation. The Arahant project makes use of already pioneered technologies to provide enlightening solutions to the problems of our day.

Abstract

In 2050 there will be nine billion people sharing the planet. Already the world is facing intertwined challenges of food, water and energy security, as well as climate change. These greatest challenges of our time are closely interlinked - the same must be true for the solutions. The Arahant project utilizes what we have enough of, deserts and the Earth’s heat, to produce what we need more of, sustainable food. This is done by combining existing and proven environmental technologies, including hydroponic farming and geothermal energy. The project aims to empower vulnerable communities in arid Ladakh with small-scale, and viable geothermal heated hydroponic farming innovation. The synergetic project is cost-effective, sustainable, and allows higher amounts of production than traditional farming, increasing resilience to resource insecurity. The project outputs include food, employment and enhanced awareness. The system already piloted in Kenya, uses local materials and labour, to minimize input costs and maintenance. Enterprise processes comprise training and consultancy, installation, provision of supplies, and commissioning. The Rolex funds will be used to install and market the first units in Ladakh. Having already communicated the intention, the immediate stage is to install a prototype in Puga Valley, where geothermal energy infrastructure already exists.

Introduction

Sufficient production of key resources, such as clean water, clean energy and a sustainable production of food, represent some of the greatest challenges of our time. It is not trivial how we go about producing these outcomes, and often the effort to solve one issue comes at the expense of another. The need for a more holistic approach to resource management is crucial and The Arahant Project Foundation was initiated to address multiple challenges with design and engineering inspired by nature.

This is done by combining already existing and proven environmental technologies, such as direct use of geothermal energy, and hydroponic farming for establishing food and water in arid areas. In this way The Arahant Project is designed to utilize what we have enough of to produce what we need more of, using deserts, geothermal springs, and the sun to produce food, water and clean energy.

Traditional production systems are set up as linear processes, turning resources into products, often with a waste-stream as a consequence. The Arahant Project integrates technologies so that waste-streams from one industrial process are used as a resource for another. In this way we bring about a significant change to the traditional production systems and allow for a kind of growth that goes beyond being simply sustainable. This has been termed “Restorative Growth” and it is defined as revegetation and the creation of green jobs through profitable production of food, water, biofuels and electricity.

The main aim of the Arahant Project is to build a state-of-the-art cascading geothermal greenhouse facility in Puga Valley. The greenhouse will specialize in growing vegetables and fodder hydroponically as well as biofuels and sustaining an animal husbandry. Heating of the facility is planned to be provided by geothermal energy. Wells and heat pumps for extraction and distribution purposes as well as sealed turbo generators are currently being installed in the area. The resulting infrastructure will harvest about 50-95 kilowatts of thermal energy (kWt) of heat and cogenerate about 10 - 15 kilowatts of electrical energy (kWe) and ~ 75 kWt of heat for space heating applications (at 20-35°C).

The specific aims of the Arahant Project include:

· To harness geothermal potential for direct heat applications in Puga Valley, Ladakh

· To built a sustainable cascading greenhouse system for hydroponic crop cultivation

· To provide affordable and higher yields of crops for human and animal consumption

· To provide green employment and generate wealth in an economically depressed region

· To reduce pressures on local water and food resources, thereby building resilience and contributing to the Indian climate change adaption scheme

Methodology

Summary

The proposal is to construct a cascading geothermal greenhouse, comprising consumers and plant growing systems connected in series, each utilizing the waste from the preceding (for example, electricity generation + greenhouse heating + animal husbandry). Crops will be grown inside the geothermal greenhouse using hydroponic methods. Fodder and vegetables are considered to be suitable crops for growing in the demonstration unit, as there is a significant domestic market demand for high quality products in Leh and other urban areas.

Figure 1. Schematic diagram of the proposed greenhouse heating system

The geothermal production facility will comprises a supply chain such as a well, a pipe and a mechanical system (for example, piping); a heat exchanger, storage tank, circulation pumps, valves, and heat tubing or pipes in the greenhouse plant beds; and environmental controls for heat and humidity regulation; as well as a disposal system comprising an injection well, and/or storage pond to receive the cooled geothermal fluid (Figure 1). The fluid can be either reinjected into the ground to replenish the geothermal reservoir or used for other purposes such as fuelling the artificial glaciers project (e.g. Ice Stupa Project) pioneered by Mr Chewang Norphel and Mr Sonam Wangchuck, therefore providing even more benefits to the community in the form of water for land irrigation purposes.

The greenhouse will be heated at night-time and on cold days during winter by a system of pipes in a closed loop system with a heat storage buffer tank. The buffer tank is heated using geothermal brine on the primary side of a plate heat exchanger. The secondary side is a closed loop system to the tank via a variable speed pump so as to maintain maximum temperature in the tank. The heat energy in the day is stored in the buffer tank for use during the night to heat the greenhouse in order to reduce the relative humidity to below 85%. This helps keep the plants dry and reduces the fungal threat and use of fungicides.

The proposed greenhouse will be 28 m in width and 90 m in length with a growing surface area of 2520 m2 (∼0.25 hectare), an internal volume of 8,911 m3 and a total surface area exposed to outside air temperature of 3,466 m2. Assuming a growing temperature maintained at 28°C and a minimum outside temperature of 4°C, the maximum heat load to maintain growing at the desired temperature during the coldest weather is 595 kW. The geothermal fluid input will have a temperature of 80°C, with an exit temperature of 45°C, a pinch temperature of 5°C and 95% heat transfer efficiency of the plate heat exchanger. The geothermal fluid flow rate and secondary water flow in the greenhouse heating circuit required to satisfy this maximum thermal load are 4.4 kg/sec and 4.2 kg/sec respectively.

Productivity, cost and revenue generation from the greenhouse will depend on what crops are grown. Initially tomatoes and peppers would seem to be ideal as they will benefit from the heating and should be able to be marketed locally. The greenhouse will require up to four trained people for maintenance and harvesting of the crop.

The basic equipment required for a greenhouse operation in Ladakh is readily available locally as in greenhouse structures, plastic sheeting, irrigation equipment, growing troughs, etc. All of the equipment necessary for heating will have to be imported, but it is readily available from Europe and the United States.

The Greenhouse Heating System

Figure 2. Heating systems in the proposed geothermal greenhouse. Heating installations with natural air movement (natural convection): (a) aerial pipe heating; (b) bench heating. ©Zabeltitz, 1986

The Arahant Project greenhouse will maintain the right growing temperature and humidity using hot geothermal fluids sourced from a proximal geothermal spring in Puga Valley. The type of crop being grown mainly will dictate the greenhouse heating system. Tomatoes and peppers require heat to be supplied around the plant canopy, thus the heating pipe should be above the ground. In contrast, root crops like calla lilies require heated ground and in this case, the heating pipes should be buried in the ground. Therefore, the quantity of hot water required will depend upon the optimum growing temperature for the selected crop, size of the greenhouse, and the lowest outside temperature expected in the area. Heat to the Arahant geothermal greenhouse and crops will be distributed through a combination of (a) aerial pipe heating (finned pipe), and (b) bench or ground heating systems (Figure 2).

The heat will be extracted with the aid of a heat exchanger and a heat storage tank (buffer). At the well, the steam that comes out of the ground at 84ᵒC will be transported to the greenhouse site through an insulated pipe. The heat exchanger transfers the heat from steam to water in a closed circuit, which then heats up the water in the heat storage tank. An open buffer system allows the system to retrieve heat at any time of day or, in contrast, to add heat to the buffer at any time of day. This allows a constant temperature within the greenhouse to be maintained. Pipe rail heating is used in every path of the greenhouse, which acts as rails for the trolley. Forced air distribution systems (e.g. finned piping) will also be used to facilitate the distribution of carbon dioxide (CO2) into the greenhouse to enhance the growing environment as well as to meet specific heating requirements of some crops.

As daytime temperatures increase due to seasonal and/or daily temperature changes then the flow of geothermal water to the greenhouse heat exchangers would be cut back. Heat load requirements would be automatically adjusted using signals from temperature sensing instrumentation.

Regulating the heat input into the greenhouse in a hot water heating system is achieved by bypassing a portion of the return cool fluid into the input leg of the heating system. A 3-way auto control valve, using input data from temperature sensing instrumentation located inside and external to the enclosure, controls the amount of fluid by-passed and thus the temperature of the water circulating through the heating pipes.

Greenhouse construction will comprise an inflated double polyethylene film with gables and sidewalls of glazed twin-wall polycarbonate. An interior set point for temperature varying from 22-28ᵒC will be considered. The temperature and humidity inside the hydroponic fodder system are controlled using a thermostat, to ensure higher growth and the best nutritional value possible. The greenhouse will also be constructed with a water circulation system that facilities water recycling, which results in lower water usage compared to conventional farming solutions.

The Hydroponic Farming System

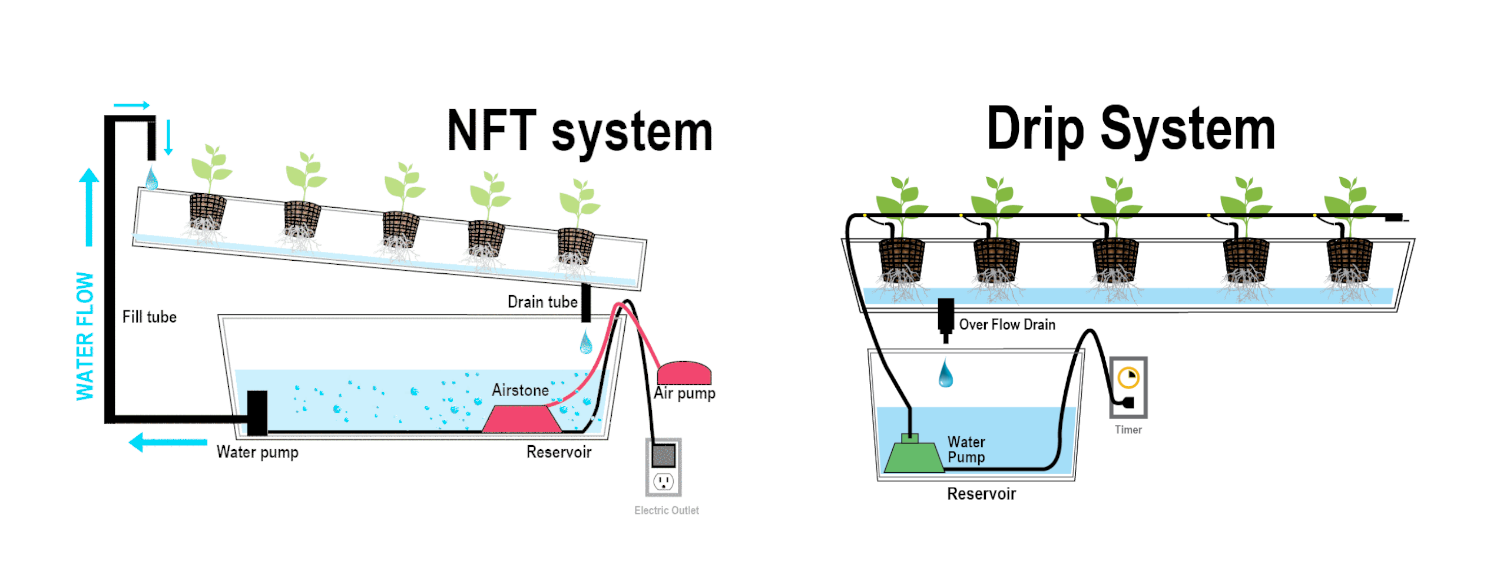

Figure 3. The hydroponic systems to be used in the Arahant Greenhouse. (Left) Nutrient Film Technique and (Right): Drip System.

Hydroponic farming entails growing crops using mineral nutrient solutions in water thus reducing the need for soil. The hydroponic system is a growing room that is specifically developed to sprout grains or legume seeds that are very nutritious yet cost effective feed. The modern and innovative farming technology is resilient to climate change, provides superior nutritional value and faster growth at limited cost of input. Furthermore, the method is more efficient and allows for higher amounts of production than traditional field farming. The faster maturity rates of plants grown hydroponically are attributed to the fact that the plants do not have to expend a lot of energy rooting out nutrients from the soil. Additionally, one has near total control over the nutrients the plant receives. The crops are able to reach their full genetic potential because of the tightly controlled environment.

Overall, hydroponic systems can be classified in two main categories: a) open systems and b) closed systems. In the open system, the nutrient solution is mixed and applied to the plant as required, instead of being re-cycled. Examples of some open systems are: growing beds, columns made out of tubular plastics or vertical and horizontal PVC pipes, individual containers (e.g. pots, and plastic sacks). In the closed system on the other hand the nutrient solution is circulated continuously, providing the nutrients that the plant requires. Examples of closed systems include: floating roots, nutrient film technique (NFT), plastic or polystyrene pots set up in columns. Our proposed hydroponic greenhouse use closed systems such as drip and nutrient film technique systems.

Hydroponic Fodder

Figure 4. Hydroponically grown fodder using our unique drip-tray system in Nairobi, Kenya. ©Sergiu Jiduc, 2014

Hydroponic fodder is young tender grass grown from a cereal grain (mostly barley), in just 5-7 days. In essence it replaces grains like dairy meal, pig’s feeds and poultry feed concentrates. Hydroponic fodder is considered to be the best livestock feed (Figure 4).

The basic concept behind hydroponic fodder is unlocking nutrients from 30% digestibility to up to 85%. This is due to the activity of enzymes produced by the seed after soaking. These enzymes are able more efficiently to convert carbohydrates to sugars, proteins to amino acids, and solid fat to lipids from the seed. Moreover the enzymes produce highly efficient hormones, growth promoters, vitamins and minerals. The role of hydroponic nutrients is to increase protein content in the crop from 9% to 25%. This is brought by the nitrogen component of the solution, which is converted to protein by the activity of enzymes. Scientific studies showed that 1kg of green feed are nutritionally equivalent to 3 kg of lucerne. Moreover, the protein content of oats for example increases from 8% as a grain to 21% as an eight-day-old green feed. The germination of barley/oats seeds activates certain enzymes that in turn change the starch, protein and fats in the grain into simpler forms in the plant. Starch is changed into soluble sugars, which are generally better utilized in the rumen. The digestible fibre content of the green feed rises from 4.2% to 9%.

The hydroponic fodder system uses photochemically treated aluminium trays to grow fodder, which inhibit the growth of fungus and incidence of other pathogens. A selection of seeds are put into the trays without soil and sprayed with hydroponics nutrients at predetermined intervals at set temperature and humidity inside the hydroponics system to ensure higher growth and best nutritional value possible. After 7 days the fodder is removed from the tray, fed to the animal, and newly seeded trays are pushed to the chamber. The animal will consume everything including the root system, leaves and nuts so there is no waste.

Animal Husbandry

Grazing livestock such as sheep, goats and yaks may provide an efficient way to harvest fodder grown at the Arahant Project facility. Grazing is less costly than harvesting and packaging fodder for sale offsite, and the grazing animals return nutrients to the soil directly through their manure. Native fodder species are well suited for grazing, and highly nutritional barley can be grazed in a controlled manner.

Allowing controlled grazing on parts of the land revegetated with fodder will not only provide locally grown food to livestock in a region where animal feed is largely imported, but at larger scales will also reduce overgrazing pressure on other parts of the desert landscape. The Arahant Project will thus not only make its own lands more productive, but will catalyse the recovery of other desert areas to a healthier state.

Benefits

Geothermal Energy

Geothermal energy production and use generally has a well-deserved image of an environmentally friendly energy source when compared with fossil fuels and nuclear energy. The direct thermal uses of geothermal energy are viable and cost-effective. Most greenhouse operators worldwide estimate that using geothermal resources instead of traditional energy saves about 80% of fuel costs – about 5-8% of total operating costs. Furthermore, the relatively rural location of most geothermal resources also offers advantages, including clean air, few disease problems, clean water, a stable workforce and often low taxes.

Generally, once the capital cost of installing the well and piping has been covered, the running costs of the geothermal energy are lower than for other energy sources and maintenance can usually be done by the user. For operations in rural areas such as in Puga Valley, the cost of installing the geothermal greenhouse may be similar to, or even cheaper than, setting up fuel storage facilities or constructing power or gas lines from the nearest retail source. Having direct control over the energy source provides certainty, and avoids economic shocks of sudden increases in energy costs or changes to the conditions of use.

The direct use payback potential is dependent on many factors including what crop is grown in the greenhouse and its market. Typically the direct use geothermal heating will give increased production per hectare, yield a reduction in or actual elimination of the use of fungicides, and a reduction in the reject levels of the crop from diseases, with the overall benefit being about a 20 to 30% increase in productivity as well as improved reliability and consistency of supply.

A summary of the key benefits of using direct use geothermal energy can be seen below:

a) Cost-effective and viable

Highly energy efficient

Higher first costs, but lower life cycle costs

Proven technology

70% renewable energy

Suitable for residential, commercial or industrial

Typically 15-25 year life

b) Environmental Friendly

One of the least polluting forms of energy.

Low levels of chemicals in low temperature geothermal fluids - little impact on ecosystems.

Reduced atmospheric emissions compared to diesel and fossil fuels, especially CO2.

Modest land requirements.

Can co-exist with other land uses.

Hydroponic Farmng

In arid regions where water is scarce, one can grow a wide spectrum of crops using hydroponic technology. Since hydroponic systems deliver water and nutrients directly to the plants, they can be grown together closer without starving each other, and healthier plants contribute to higher yields. By growing crops in a clean environment, under ideal conditions, hydroponics saves the cost of soil preparation, insecticides, fungicides and losses due to drought and ground flooding.

A summary of the key benefits of using hydroponic farming can be seen below:

Grows all year round providing a constant food supply

There is reduced turnaround time between planting as no soil preparation is required

As one has control over the growing conditions, the crops are protected from the outside climate and production can be timed more effectively to satisfy market demand

Plants have a balanced supply of air, water and nutrients ensuring that they reach full genetic potential in terms of productivity

Minimizes water usage / maximizes re-usage

The plants are more robust and therefore resistant to pests and diseases

There are no troublesome weeds, and stray seedlings thus removing the need for costly and harmful chemicals (pesticides etc.)

Produces greater amounts of food in less time. For example, one is able to produce 3 – 4 times more vegetables in a shorter period than in conventional farming).

Produces less waste

Uses significantly less land (thereby potentially enabling farmland to be reclaimed, reducing our environmental impact). Furthermore, it provides stable and significantly increased yields and shorter crop maturation cycle can be utilized by families with small or no yard space

Reduced labour requirements

Crops have a high nutritional value, improving the digestibility of the consumer

Crops are highly pest resistance

Environmental Impact Assessment

The main environmental impacts from the proposed geothermal development are site preparation for drilling and completion, and disposal of geothermal fluids after heat extraction. By reinjection of spent fluids, the environmental impact of geothermal fluid withdrawals can be minimized. The impacts from greenhouse (e.g. heated) construction and operation are site development (e.g. levelling and road building), site run-off, water use and its impact on local water resources, and waste water discharge, particularly with regard to fertilizer and pesticides contamination (Note: the use of fertilizer and pesticides is minimal in hydroponic farming compared to traditions techniques). A detailed impact statement will be developed for any specific site. But by using geothermal energy instead of diesel-burning back-up generators, there will be less air and noise pollution around the sites. There are also additional environmental impacts resulting from operating a greenhouse. These operations can particularly impact water use and quality. The consumption of irrigation water and the discharge of wastewater from greenhouse businesses can negatively impact the local environment. Pest and fungicide control, although minimal in hydroponics farming can still have medium to high environmental impacts. Use of geothermal energy to heat and dehumidify greenhouses to prevent night time condensation and eliminates the threat of fungus and mould growth, and thus eliminates the need for herbicides which has a positive environmental impact.

Location

The Puga Geothermal Field

The Puga geothermal field, located in the northwestern part of Himalayas, is recognized as the most promising area among the various geothermal zones identified in the Indian Sub-continent (Figure 5 and 6). It forms a part of the Himalayan geothermal belt, located in the southeastern part of Ladakh district, Jammu and Kashmir State in India, at an altitude of about 4400 m. The Puga valley is surrounded by hills rising up to an altitude of about 6000 m, forming the Puga region as a valley. The 15 km long and about 1 km wide valley trends nearly east–west in direction between Sumdo village in the east and Polokongka La in the west. This area, positioned just south to the Indus Suture Zone, has hot springs with surface flow temperatures up to 84ᵒC (the boiling point of water at that altitude). Borax and sulphur, which are generally connected with thermal fluids, occur widely in the eastern part of the valley. The valley appears to be a down faulted block with its northern and southern faults concealed under the valley material (Ravishanker et al., 1976). It consists of recent to sub-recent deposits of glacial moraines, eolian sand, clay and scree.

Field Characteristics from Magnetotelluric Investigations

· NW Himalaya, Ladakh district, Jammu and Kashmir, India, is situated near the junction of the Indian and Asian plates;

Figure 5. A geothermal hot spring in Puma Valley. ©Sergiu Jiduc, 2016

The thermal activity is attributed to the widespread igneous activity during Upper Cretaceous to late Tertiary age;

Located at an elevation of 4400m;

The valley trends in almost E–W direction, between Sumdo Village in the east and Polokongka La in the west, over a stretch of about 15km with a maximum width of about 1 km;

The Puga area lies adjacent to the south of the Indus Suture Zone (ISZ) which has been believed to be a major crustal subduction zone, confirmed by the discovery of blue schist facies from its basic rocks;

Thermal manifestations come in the form of hot springs (over 100), hot pools, sulphur condensates, borax evaporates (Figure 5);

Source, partial melts at a depth of 1.5 – 2km where temperature exceed 200°C;

Aerial extent 3km2;

34 boreholes at depth between 28.5 to 384.7m;

Hot spring temperature varies between 30°- 84°C (latter being the boiling point of water at that elevation);

Maximum observed discharge from a single borehole Qmax= 30-40 l/second. Cumulative Maximum discharges from the natural springs Qmax= 300l/second with Qmax= 5 l/second for a single spring;

More than 5000 MW available.

Figure 6. Puga Valley. ©Sergiu Jiduc, 2016

Challenges

The Arahant Project might encounter several challenges such as: i) execution difficulties, particularly due to engineering challenges and/or environmental difficulties such as extreme weather events, high altitude, and the remoteness of the site which can waste time and resources; ii) diffused decision making due to cultural and language differences or late access to updates and information; iii) delays due to bureaucratic obstacles; iv) unrealized business value (when deliverables arrive late or incomplete) and fragmentation of planning processes and resources which can lead to an inability to systematically communicate and fine tune multiple project scenarios, resulting in regular unforeseen slippages and problems. Last but not least lack of funding or delays in receiving funding which can alter the quality of the project delivery. The management team throughout the lifetime of the project will carry out a continuous risk assessment to mitigate any foreseen and unforeseen challenges. At present the main challenges we have encountered included bureaucratic obstacles from our Indian stakeholders, which resulted in time wasting.

Opportunity

Figure 7. The Puga Nomadic School which could benefit from the Arahant Project and become a sustainability center in the region.©Sergiu Jiduc, 2016

Realizing the potential of geothermal energy in Leh, a project has been initiated jointly by the Indian Institute of Technology Bombay (IITB), The Hill Development Council of Ladakh, Ladakh Ecological Development Group (LeDEG) and Ladakh Renewable Energy Development Agency. Under this initiative, the thermal discharges from the existing bore-wells in Puga valley alone will be developed in two phases. During the first phase two heat pumps, each capable of recovering 50-95 kilowatts of thermal energy (kWt) of heat for space heating, water heating, greenhouse cultivation and ice-melting applications will be developed and deployed. During the second phase the 50-75 kWt heat pipes will be integrated with sealed turbo-generators for cogenerating about 10-15 kilowatts of electrical energy (kWe) and ~ 75 kWt of heat for space heating applications (at 20-35°C). The Puga valley geothermal resources will also be utilized for supporting a number of Tibetan residential schools. These schools will be self sufficient with respect to power, space heating and vegetables. Once successful, the Indian Government plans to install similar systems at Chumathang. Similarly the steam discharge will also be utilized directly for generating power in Puga valley. Greenhouse cultivation is required since all the vegetables are flown either from Delhi or from Chandigarh and the army is supplying vegetables to the rural Leh population at affordable cost.

Innovation

This cascading system is pioneering geothermal hydroponic farming in India to generate sustainable food. The synergies arising from integrating technologies improves the system’s performance and economics. The greenhouse is designed to overcome local environmental problems, particularly aridity, water scarcity, and accelerated climate change. Heating is provided by the direct use of geothermal energy allowing appropriate temperature control, particularly during the night and winter. Furthermore, the greenhouse is equipped with double polyethylene glazing to reduce heat loss through the walls and enhance overall efficiency. Crop hydration is provided by gravity water circulation systems, and plant health is guaranteed by the use of photo-chemically treated trays, which inhibit the growth of pathogens. Wastewater from the system is used for further irrigation purposes (e.g. artificial glaciers). The project allows automation and technology extensions including the development of high-quality, non-toxic, renewable, and biodegradable biofuels, (e.g. algae, and barley fodder), animal husbandry and electricity generation.

The Arahant project uses a unique and patented fodder generation system as well vegetable growing systems that have been pioneered in Kenya. The core technologies such as geothermal greenhouses and hydroponic farming are indeed well established elsewhere in the world such as Europe, United States and New Zealand. However, the Arahant project has combined and adapted these proven technologies in order to work in the Ladakhi high-altitude and arid landscape. There is no other geothermal hydroponic greenhouse currently operating on Indian soil. The Arahant Project will be the first to bring the synergetic farming technology to the sub-continent.

Our overall aim is to innovate farming and food production in an economically deprived, and resource scarce area and bring about sustainable change in the form of green employment, economic inclusion and greater resilience to climate change.

Impact

The project addresses unsustainable farming techniques by providing an alternative, nutritious, affordable, efficient, waste-free and resilient food production method that conserves water and energy and improves digestibility. It enables farmers to achieve predictable, high yields for vegetables, fruit and fodder and increases crop diversity since no soil is required. The crops are unaffected by seasons and adverse weather conditions, consequently reducing costs and increasing community resilience to climate change.

The project ensures family nutrition and household food security; removes gender related barriers; and encourages income-producing employment for chronically disadvantaged segments of the population entrapped in an economically depressed region. Such employment produces tax revenues as well as personal incomes, reducing the need for welfare and improving quality of life. The development and use of hydroponics have enhanced the economic wellbeing of many communities throughout the world. There is also potential for scaling-up across the region with Bhutan expressing high interest.

Impact evaluation is about attributing impacts to the project. A comparison group will measure what would have happened to the project beneficiaries if the project had not taken place. For evaluation purposes, we will spell out the target population for the intervention and how the ultimate beneficiaries will be selected. This will provide the tools for developing the initial strategy to identify project impacts. Furthermore, a plan will be crafted about how the implementation will be rolled out for the project and its components. This will provide the evaluation with a workable framework for timing data collection activities, as well as help in the development of a strategy to identify project impacts.

We will measure the project’s impacts through a combination of specific and measurable indicators such as:

Jobs created (number)

Food produced (tonnes)

Water conserved (litres)

Beneficiaries (number)

Energy conserved (kJ/kWh)

Carbon footprint (tonnes, CO2)

Awareness generated

Revenue (USD)

Bibliography

Arora, C.L., Singh, H., Das, L.K., Ghatak, T.K., Singh, R.P., Hakim, A., 1983. Geophysical exploration of the Puga Valley geothermal field, Ladakh District, Jammu and Kashmir State. Spec. Publ.-Geol. Surv. India 2, 631– 646.

Baweja, B.K., 1968. A Note on Visit to the Hot Springs at Puga Valley, Ladakh. Report of the Hot Spring Committee. Central Water and Power Commission, India. unpublished.

Carlini, M., Monarca, D., Biondi, P., Honorati, T., and Castelluci, S. 2010. A Simulation Model for the Exploitation of Geothermal Energy for a Greenhouse in the Viterbo Province. International Conference Ragusa SHWA 2010, Italy.

Chandrasekharam, D. 2005. Geothermal Energy Resources of India: Past and the Present. Proceeding World Geothermal Congress, Antalya, Turkey. 24-29.

Chopra, P.N. 2005. Status of the Geothermal Industry in Australia, 2000-2005. Proceedings of the World Geothermal Congress 2005, Antalya, Turkey, 24-29 April.

Dellinger, M., and Cooper, G. 1990. Greenhouse Heating with Low temperature Geothermal Resources in Lake County, California. GHC Bulletin.

Fridleifsson, I.B. 2001. Geothermal energy for the benefit of the people. Renewable and Sustainable Energy Reviews., Vol. 6, pp299-312.

Harinarayana, T., Azee, K.K.A., Murthy, D.N., Veeraswarmy, S.P., Rao, S.P.E., Manoj., C., and Naganjaneyulu, K. 2006. Exploration of geothermal structure in Puga geothermal field, Ladakh Himalayas, India by magnetotelluric studies. Journal of Applied Geophysics 58: 280-295.

Harinarayana, T., Azeez, K.K.A., Naganjaneyulu, K. Manoj, C., Veeraswarmy, K., Murthy, D.N., and Rao, S.P.E. 2004. Magnetotelluric studies in Puga valley geothermal field, NW Himalaya, Jammu and Kashmir, India. Journal of Volcanology and Geothermal Research. 138: 405-424.

Hillensheim, M., and Mosey, G. 2013. Feasibility Study of Economics and Performance of Geothermal Power Generation at the Lakeview Uranium Mill Site in Lakeview, Oregon. Natural Renewable Energy Laboratory. Technical Report. NREL/TP-6A10-60251.

Lindal, B. 1973. Industrial and other applications of geothermal energy, In Geothermal Energy: Review of Research and Development, Paris, UNESCO, LC No. 72-97138, pp135-148.

Lund., J.W., and Boyd, T.L. 2015. Direct Utilization of Geothermal Energy 2015 Worldwide Review. Proceedings World Geothermal Congress, Melbourne, Australia.

Lund, J.W., Chiasson, A., and Boyd, T. 2006. Executive Summary: Assessment of Greenhouse Heating options with Geothermal Energy. World’s Greenhouse, Oreana, Idaho. Geo-Heat Center.

Lund, J.W., Freeston, D.H., and Boyd, T.L., (2005) Direct application of geothermal energy: 2005 worldwide review. Geothermics, Vol. 34, pp691-727.

Mohamed, M.B. 2003. Multiple integrated use of geothermal resources in Kebili region, southern Tunisia. International Geothermal Conference, Reykjavik. 13-21.

Practical Hydroponics and Greenhouses. 2013. Hydroponics in India (In Press). 17-23.

Raina, B.N., Nanda, M.M., Bhat, M.L., Mehrotra, P.C., Dhal, B.N., 1963. Report on the investigations of coal limestone borax, and sulphur deposits of Ladakh. Unpublished progress report, Geol. Surv. India.

Ravishanker, Padhi, R.N., Arora, C.L., Prakash, G., Thussu, J.L., Dua, K.J.S., 1976. Geothermal exploration of the Puga and Chhumathang geothermal fields, Ladakh, India. Pr. 2nd U. N.Symp. On Development and Use of Geothermal Resources, vol. 1, pp. 245– 258.

Sharma, O.P, and Trikha, P. 2013. Geothermal Energy and Its Potential in India (in Press). Vol.7. Issue.1: 14-18.

Singh, R.P., Nabetani, S., 1995. Resisitivity structure of Puga geothermal field. Proc. of World Geothermal Congress, Florence, Italy, 18–31 May, 1995.

Singh, S.B., Drolia, R.K., Sharma, S.R., Gupta, M.L., 1983. Application of resistivity surveying to geothermal exploration in the Puga Valley, India. Geoexploration 21 (1), 1 – 11.

Thain, I., Reyes, A.G. and Hunt, T., 2006. A practical guide to exploiting low temperature geothermal resources, GNS Science Report 2006/09. 76p.

U.S. Department of Energy. Energy Efficiency and Renewable Energy. Geothermal Technologies Program. Direct Use. (In press).

USAID, Land O’Lakes International Development and WInrock International, and The Kenya Geothermal Development Company (GDC). 2013. Priority Geothermal Direct-Use Applications for Kenya: A Pre-Feasibility Study for Greenhouses.

Virdi, N.S., Thakur, V.C., Kumar, S., 1977. Blueschist facies metamorphism from the Indus suture zone of Ladakh and its significance. Himal. Geol. 7, 479–482.